Airbus E-Fan Prototype |

From the Wright Brothers' first flight at Kitty Hawk to the dawn of the Jet Age, almost every airplane was powered by an internal combustion engine---most using gasoline. Turbines eventually replaced gas engines for virtually all large aircraft operations, but in light general aviation (GA) singles and twins, gasoline-fueled, horizontally opposed, air-cooled reciprocating engines remain the standard powerplant today.

That's beginning to change. High-powered (usuÂally turbocharged) versions of those engines operating at high compression require leaded fuel---which is on the way out, for both environmental and economic reasons. In Europe, leaded aviation gasoline is hard to find and expensive. In the developing world, it can be almost impossible to get. So, a couple of old engine types are getting a new look---along with radical new technologies that may change aviation beyond all recognition in coming decades.

Diesels Make A Comeback

One old technology that's making a comeback is the diesel---named for inventor Rudolf Diesel, who came up with the idea more than 100 years ago. Diesels operate on the principle of compression ignition---instead of using a spark plug to ignite the fuel-air mixture, in a diesel, the fuel is compressed to the point that it ignites on its own. That has two big benefits and one major downside: Pre-detonation or knock, which we work so hard to avoid in conventional engines, isn't a problem for a diesel---it's actually what makes the engine work. Another benefit is that diesels can run on a wide range of fuel types ---most significantly for aviation applications, Jet-A is fine. The downside is that the engine has to be built stronger to contain the power of a fuel charge detonated at maximum compression. So, as a rule, diesels tend to be heavier than spark-ignition engines for a given power output.

Allen Schaeffer, Executive Director of the Diesel Technology Forum (an industry group) told me there's an additional advantage for diesels---high energy density: "A gallon of diesel has about 10% more BTUs than gasoline. The engine is also the most thermally efficient internal combustion engine design. Commercial truck engines exceed 50% thermal efficiency versus gasoline engines, which are typically half that." His group expects global consumption of diesel fuel to exceed gasoline by the end of this decade for commercial applications, which can only mean that gasoline will be harder to get---and more expensive.

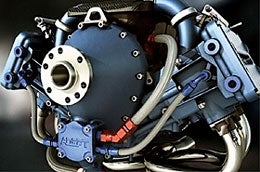

AEPS Vision 350 AEPS Vision 350 |

The efficiency and high energy density of diesel has been noted and touted by several manufacturers, notably the German firm Thielert AG, which began selling aircraft diesels based on modified Mercedes-Benz auto engines back in 2002. Unfortunately, while the engines---which at first had a poor reputation for reliability---improved over time, the company went bankrupt in 2008. Its assets were acquired by Continental Motors last year, which is now building 135 hp and 200 hp Centurion engines based on Thielert's design, with applications including a complete "firewall-forward" conversion kit for Cessna's C-172 Skyhawk.

Engineered Propulsion Systems (EPS) is a new company with big plans for higher-powered aircraft diesels. Their Graflight V-8, which founders Michael Fuchs and Steven Weinzierl call a "clean-sheet design" exploiting "new materials from automotive and trucking industry to keep weight competitive to conventional engines" is designed to fit in the same space as a conventional turbocharged engine in the 320-450 hp range. The Graflight engine makes extensive use of new technologies, including advanced materials and electronic control. The founders concede that like other diesels, theirs will be heavier (in their case by about 7% when installed) than an equivalent gasoline engine, but they expect the high efficiency of their engine---combined with the high energy density of Jet-A---will give a big benefit in fuel burn (and range). For instance, my 1975 Cessna C-182P Skylane burns about 13 gallons of 100LL per hour. According to EPS, one of their Graflight V8 engines would deliver the same power while burning only nine gallons of Jet-A per hour. And they expect the engine to be more reliable, with a time between overhauls (TBO) as high as 3,000 hours, once the engine is fully developed.

EPS and Continental aren't the only companies betting on diesel technology: SMA, a subsidiary of the French (mostly) conglomerate Snecma S.A., has developed a 230 hp diesel that's licensed by Continental. An Austrian company, Austro Engine, was founded in 2007 by Diamond GmbH after they became concerned about problems at Thielert, and builds diesels in the 170 hp range.

Continental 135 hp Diesel In A Skylane |

You may notice that most of the companies named so far are European. That's no accident: Aviation gasoline is both expensive and hard to find on the other side of the Atlantic!

Liquid Cooling

There's another item all of those vendors have in common: Unlike virtually all current production gasoline aero engines, most diesels are liquid cooled (SMA's is an exception). Liquid cooling has advantages, including no risk of "shock cooling" in low power descent from altitude, but it's usually expected to add weight.

Adept Airmotive claims to have found a way around that. According to spokesman Lee Brinley, the company is working on liquid-cooled engines offering power from 260 to 320 hp that will offer "considerable weight savings, superior engine management, fuel efficiency and reduced maintenance costs."

Adept Airmotive Adept Airmotive |

Weight savings? From a liquid-cooled engine? Yes, according to Brinley, who told me that Adept's high-output 320T is expected to be up to 200 pounds lighter than a Continental TSIO-550. Like most of the engines discussed so far, Adept uses a gearbox, so that the engine doesn't have to run at the same RPM as the prop---but unlike others, Adept isn't building a diesel. Instead, their engines are spark-ignited and multi-fuel, designed to run on avgas, premium-grade automotive gasoline---includÂing blends with ethanol---or even base-grade unleaded (at reduced power setÂtings). According to Brinley, Adept has been working on their engine design for over 10 years, and it has been flying for four years. The company expects to certify the engine by 2017. It will initially be seen mainly in experimental aircraft, and the company is also talking to a number of OEMs.

Lycoming TEO-540 |

For a reality check on these developments, I spoke with Jack Kane of EPI Inc., which specializes in custom high-performance engine conversions (among others, he was responsible for the engine in the Sweet Dreams racer). Kane has wide experience with both liquid- and air-cooled engines, and warns that cooling system design is a significant issue regardless of engine type. While a liquid-cooled engine doesn't require air flowing directly over the cylinders, it most certainly does require some way to transfer heat away from the coolant---and getting that right isn't simple. He's leery of claims about simply bolting on a completely different engine type in an existing airframe.

Other manufacturers are sticking to conventional air-cooled gasoline engine designs, but using electronic ignition to improve efficiency and enable the engine to run on multiple fuel types. This includes Lycoming's 350 hp TEO-540-EXP, which also features single-button start and single-lever power control. Lycoming is also widely reported to have a diesel engine (the company didn't deny that when asked), but so far it's used only for drones.

PBS Engine On A Sonex Experimental Jet |

Baby Jets

If liquid cooling and diesels running Jet-A aren't different enough for you, how about bringing GA airplanes into the jet age directly? That's possible today, at least where turboprop power plants are concerned (see our recent feature on engine conversions), but only for six-seat singles and twins, and only if your budget can stand a high six-figure hit. Ditching the propeller and going with a full-jet powerplant, you'll need seven figures, at least.

Maybe not! Czech company PBS Velká BÃteÅ¡, a.s., sells a small (2.5-foot x 10-inch nacelle), lightweight (43 pounds) TJ-100 turbojet that has been used in a variety of experimental aircraft. Like all turbojets, it isn't exactly stingy on fuel---burning over 30 gallons per hour---and it isn't exactly what you want for short takeoffs. Still, Bob Carlton of Desert Aerospace, who has worked on several PBS applications, says it's exciting: "Jet thrust is not the same as thrust from a prop. Prop thrust decreases with speed, jet thrust increases with speed. In car terms, a prop is like having only first gear (or first and second with constant speed). A jet is more like only having sixth." While unwilling to discuss specific performance on his latest project, in general terms: "The feeling of flying a small jet like the Sonex is amazing. It is glass smooth, even at 250-plus mph. No engine vibration, no prop turbulence; just pure, unadulterated speed!"

What makes this interesting is the low cost of the TJ-100, which sells for 44,600 Euros (about $56,000 as this was written), making it cost-competitive with conventional piston engines, at least for initial purchase. Life-cycle cost may be another matter: Carlton told me that the inspection interval for the engine is currently just 300 hours, though he added "that should increase as we get more experience."

Perhaps more important for most of the GA world (I cringe at the notion of what the FAA might do if asked to certify a jet-powered four-seater), PBS is also working on a small turboprop engine based on the same technology. The TP-100 weighs less than 200 pounds, but generates over 240 hp. It's flying now in an RV-10 experimental aircraft.

Electric And Hybrid Propulsion

Over the past few years, a number of truly exotic experimental propulsion systems have been demonstrated---notably, solar-electric propulsion that the Swiss explorer Bertrand Picard expects will enable him to fly around the world with zero emissions (aside from those generated in building his Solar Impulse) within the next few years. But, I didn't expect to find such an exotic technology that would impact the GA community any time soon.

At this year's Farnborough air show in England---and again at EAA AirVenture in Oshkosh, Airbus publicly flew their E-Fan, an electric-powered two seat prototype that flies for about an hour on stored power from batteries in the wings. They've announced production plans for a two-seat trainer and a four-seat general purpose version that will be a hybrid: It will use power from both a battery pack and an auxiliary engine for endurance of over three hours. Airbus isn't the only company interested in this sort of thing. While researching this article, I discovered a group at the University of Colorado working on a hybrid electric/internal combustion engine specifically aimed at small airplanes. One of the sponsors is Boeing, which I suspect isn't about to let Airbus cement a lead on engine technology that will surely be scaled up for larger applications if it proves out in GA.

As the folks at Adept pointed out, over the last 20 years, there has been a revolution in other aspects of GA---glass panel flight decks, composite airframes, GPS guidance---but not in the engine. While it's unlikely that electric aircraft proÂpulsion will displace conventional liquid fuels any time soon, its appearance certainly drives home the point that engines are changing---which really was about due!

For More Information:

|

|

| Aircraft Engine Historical Society www.enginehistory.org Diesel Technology Forum www.dieselforum.org Safran SMA www.smaengines.com Austro Engine GmbH http://austroengine.at Engineered Propulsion Systems (EPS) http://eps.aero/the-eps-engine EPI, Inc. www.epi-eng.com |

Lycoming iE2 http://lycoming.com/Lycoming/ OURINNOVATION/TheIE2Difference.aspx Desert Aerospace www.desertaerospace.com Airbus E-Fan www.airbusgroup.com/int/en/story- overview/future-of-e-aircraft.html SOLSTICE Hybrid Drive www.colorado.edu/honorsjournal/ content/solstice-hybrid-drive-turning- point-aircraft-propulsion |

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox