The Lancair Evolution: An Evolving Standard Of High Performance

The turbine-powered kit aircraft heads for the backcountry

|

When Lancair began transforming the high-performance experimental aircraft world with its composite kits in the 1980s, who knew its advances would reverberate all the way into the backcountry? But with the optional Rough Service Landing Gear (RSLG) introduced last year, opening grass, gravel, and other non-paved surfaces to the turbine-powered and pressurized Lancair Evolution, the company has seemingly created the ultimate bush plane---a rugged four-place with a 1,800-pound useful load and a near 300-knot cruise speed.

Doug Meyer, Director of Sales and Marketing of the Redmond, Ore., company, chuckles at the suggestion---after all, you're not going to squeeze an Evolution in and out of a 300-foot clearing like some light fabric aircraft on balloon tires. Besides, customers have been buying and building Evolution kits since 2007 for speed, performance and turbine reliability. But, Lancair has customers "in Brazil, Russia, the Czech Republic and South Africa who say, 'I need to be able to land on the road,' or wherever." That's what sparked development of the ruggedized gear.

Natural Adaptation

The RSLG puts the welcome sign on hundreds of turf fields and backcountry strips most thoroughbred aircraft would only be seen at in the event of an emergency. Like Airport Manatee (48X) on Florida's Gulf Coast, a 3,500-foot turf strip---about 2,000 feet of which went unused when the Evolution's reverse thrust was deployed after landing---that just about any GA pilot would enjoy dropping into. A dozen or so airport denizens gathered around N38SP. "It's a little awe-inspiring," airport manager Tom Reeder tells me. "Most of us down here in the grassroots, we're not used to seeing something like that."

Meyer fields questions he has heard many times, such as those about the distinctive ovoid windows. "The windows are for looking through, not for looking at," Meyer says. "They're shaped this way not because of pressurization, and not because they're inspired by Burt Rutan, but because they provide the best visibility. It's ergonomically correct. Some people don't like the way they look, but as soon as they get in the airplane they say, 'Oh, now I get it.'"

Warranties and insurance are other issues asked about; owners pour more than a million dollars into the build. What happens if something goes wrong with the airplane?

"You've got a Pratt warranty on the (750 hp PT6A-135A) engine, you've got a Hartzell warranty on the prop, you've got a Garmin warranty on all the avionics, and we, as the manufacturer, warranty all the mechanical parts," Meyer says. But what about damage to the airframe? "It's carbon fiber," Meyer answers. "It's going to be there when the dinosaurs come back." He slams his arm into the fuselage like he's blocking a 300-pound lineman and invites me to do the same---something you wouldn't do to an aluminum airframe. "A hammer will bounce off of that, no problem," Meyer says. This isn't wet layup fiberglass, he adds, but high temperature-cured carbon fiber, the same material and process Boeing uses to build B787 Dreamliners.

Lancair Evolution co-owner Stuart Parker and N38SP Lancair Evolution co-owner Stuart Parker and N38SP |

Yes, you can build this aircraft from a kit! |

Hull insurance is available for the Evolution just like for any other aircraft, except that owners who have only flown fixed gear ("We see Cirrus guys with 3,000 or 4,000 hours and no retractable gear time," Meyer says) pay a penalty until they've accumulated at least 200 hours of retract experience. For buyers with no turbine time, "We recommend taking a one-day turbine transition course with Simcom or FlightSafety." Indeed, for anyone who flies a high-performance single, transition to the Evolution, with its 61-knot stall speed, is simple, Meyer says.

Buyers, Builders And Owners

But unlike high-performance turbine singles from Piper, Daher and Pilatus, the Evolution is a kit aircraft; if you want one, you're supposed to build it. Surely not all the owners of these million-dollar- plus machines actually construct them?

They do, Meyer asserts, and the build time is about eight to 10 months, with buyers first participating in a two-week owner-assistance building program at Lancair's Oregon factory. "After two weeks, you have the basic airframe from firewall aft sitting on the main gear, so everything critical for strength, aerodynamic safety and flying qualities is assembled," Meyer said. From that point, most owners engage one of six authorized professional build centers to assist with the completion, and owners spend several weeks over the next few months working on the airplane to ensure they build at least 50.1% of the aircraft as mandated by FAA rules. "We do not mess with that system," Meyer says. "We operate to the letter of the law, and the FAA inspectors who inspect the airplane understand that, and they're happy with what we do."

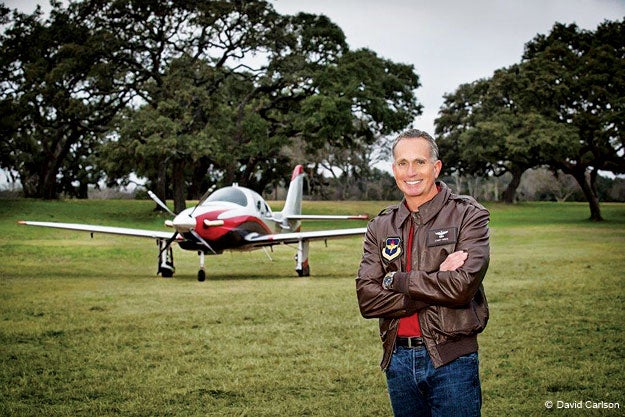

Doug Meyer, Lancair's Director of Sales and Marketing, knows the Evolution inside and out. |

But the kits and construction are simple enough that a professional builder isn't required. N38SP, for example, was built by co-owner Neal Longwill, who got his pilot's licenses after he retired and decided to build a kit airplane. "I'm not an engineer, I'm a sales and marketing person," Longwill tells me on the phone. "Even though it's the highest-performance and largest [of the Lancairs], it's the easiest one to build." In fact, N38SP is the third Evolution Longwill built. He's now an Evolution sales rep, and this is his demo aircraft.

|

N38SP's co-owner is Stuart Parker, CEO of a financial services firm and a former USAF T-38 instructor pilot who hankered to return to aviation after a 15-year hiatus. "You always have that bug in you of wanting to fly," Parker says from his home in Texas. (He had stayed up in Destin, Fla., one of the stops on a family trip, the day we flew his aircraft.) Parker started searching the Internet and spent two years "daydreaming, thinking one day I might get an airplane" before he saw a picture and read a description of the Evolution. It was actually Longwill's previous model, and a few days later, Longwill flew down to show it to Parker. "We flew for a few hours, and I fell in love. I said, 'I've got to have one,'" Parker recalls. The two agreed to partner in the demo plane Longwill was about to build, and while awaiting completion, Parker logged high-performance single time and studied the Garmin G1000. "When I left the Air Force, everything was steam gauges," he says.

Parker has about 150 hours on the Evolution, including a trip to Sun 'n Fun this year where N38SP took "Outstanding Homebuilt" honors.

"You can see someone's personality in every airplane," Parker says of Evolutions, calling attention to his "subtly aggressive" silver paint scheme with red and black accents.

The Outside View

Weighing 4,550 pounds at gross, the Evolution is bigger than it appears from across the ramp. There's not much to examine on the preflight, on or in during the mandated annual condition inspection, for that matter. The airframe has only one access panel, covering the yaw damper housing in the aft fuselage. The baggage compartment, accessible via a door on the starboard side that doubles as the emergency exit, holds 225 pounds.

The wing is elliptical, which Lancair says obviates the need for winglets, as the shape blends the wing vortex in the same manner. Each holds 84 gallons of fuel. Fowler flaps deploy to 25 and 50 degrees. The RSLG incorporates larger brake disc rotors, and bigger calipers and brake pads, and the tires are 6.5 inches wide versus the standard four inches.

The Evolution sits high off the ground, and it's a big step up, but entry into the roomy cabin is easy. The armrest top of the console dividing the front seats flips up and back, revealing the circuit breakers while also allowing the right-seat occupant to easily slip into position. The forward seats and the rudder pedals are adjustable. The side-stick controls are big and have an authoritative feel.

The Garmin G1000 is the only avionics package offered, the PFD and MFD complemented by a proprietary Lancair touch-screen control on the right side of the panel for environmental, pressurization and lighting systems. Electrical and engine switches are over the PFD.

To get underway, pull down and latch the gull-wing door. Engage the fuel pump, the igniter and starter, monitor the percentage power and temperature on the MFD in the center panel, then engage the generator. The condition lever and fuel controls are kept full forward, and only the power lever, the black handle on the left of the trio, is used to control the engine. Take the prop out of feather, and the Evolution starts to move forward. Steering is by light toe pressure on the differential brakes. A trigger under the power lever allows it to move back, putting the prop into beta range, and ground movements are controlled by combining brakes, torque and reverse thrust.

The Rough Service Landing Gear (RSLG) system is an option. The Garmin G1000 avionics suite is standard. |

The Evolution In Flight

We use a rolling takeoff with standard one notch of flaps, bringing the power up to 1,300-1,400 pounds of torque and relaxing the full right rudder as airspeed builds to 72 knots, where a bit of back pressure shoots us off the ground. The gear comes up at 100 knots and flaps at 120. Best rate of climb is 110 knots, which produces rates up to 4,000 fpm, "but nobody does that; it's too steep," Meyer says. "It will climb out light at 3,000, 3,500 feet per minute at a nice angle." We climb at 160 to 165 knots, and ascend at 2,200 to 2,500 fpm when I check the VSI. Visibility is superb, out the sides and over the nose, where the cowl is barely visible.

"I call it a point-and-shoot airplane, because on a day like today, where you've got a broken-to-scattered layer and you want to go through it, you just pick your blue hole and go through it," says Meyer. We pick a hole and climb to 16,500 feet. The pressurization system works automatically, and the cabin altitude is about 2,750 feet here.

Burning about 37 gph, we engage the GFC 700 autopilot for a speed run and see TAS in excess of 280 knots. "We advertise it as a 300-knot airplane," Meyer says. "To be frank, a lot of people don't get that because they put in a lot of cool options and amenities, and end up with a heavier airplane." The RSLG comes with a 12-knot speed penalty, as the wider tires protrude two inches into the slipstream. "The laminar flow wing is very slippery, and any disturbance to that flow will bite you," says Meyer.

Deice boots, introduced in 2014 along with the optional gear, come with a similar penalty but are proving popular nonetheless, with several aircraft slated for retrofit and new buyers ordering them. For both groups, the enhanced utility is clearly worth more than a round-number cruise speed. This August, Lancair will introduce an optional Ballistic Airframe Recovery Parachute System by BRS for the Evolution.

As impressive as the speed are the manual-handling characteristics. Early Evolutions had a reputation as being heavy on the stick. "It became an obstacle in the buying process, so we redesigned the ailerons so they're more harmonious," Meyer says.

The look of power---the engine is a 750 hp P&W PT6A-135A swinging a four-blade, 82-inch Hartzell propeller. |

Even at cruise speeds, the controls are light and the Evolution well balanced. Maintaining altitude in a steep 360 holds no challenge. Meyer trimmed for a 30-degree banked turn, and it flew around hands-off, steepening only slightly before we finally took the airplane again for the fun of hand flying. Slow flight and 61-knot stalls affirmed its docile characteristics.

If you need to get down in a hurry, dirty up the plane, pull back the power and point the nose down. "When you pull the power back, the prop acts as a pretty good speed brake," Meyer says. We descended at what seemed like a leisurely 5,000 fpm.

When nearing your destination, pull power and slow to the 160-knot flap speed and deploy the first notch. Like the unpowered spinning prop, the flaps are effective speed brakes, and you'll have to throttle up again to maintain airspeed. Now, you can descend into the pattern whenever you want, already configured for landing. Fly the pattern at the numbers of any high-performance single. Put in the second notch of flaps and look for 85 on final. Don't flare, but simply level the nose, and until then keep the power in. Pull the trigger, move the throttle back into the beta range and see the outside world suddenly come to a stop.

Meyer sums up the Evolutionary experience succinctly: "It's the coolest thing you can fly that isn't painted gray."

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox